Shop

Copper Hydroxide Nanowires

| Chemical Formula | Cu(OH)2 |

| Stock No. | NCZNW104-19 |

| Molar Mass | 97.561 g/mol |

| Density | 3.368 g/cm3 |

| Melting point | 80 ˚C |

| CAS Number | 20427-59-2 |

| Diameter | 10 nm (customization available) |

| Length | 5 µm (customization available) |

Copper Indium Alloy Nanopowder

| Product Formula | Cu: In |

| Product Number | NCZ-A-115-19 |

| CAS Number | 7440-50-8/7440-74-6 |

| Molecular Weight | 178.36 g/moL |

| APS | ≤ 80 nm (can be customized) |

| Purity | 99.9% |

| Color | Grayish Black |

| Form | Nanopowder |

| Density | 1.2 to 1.5 g/cm3 |

| Melting Point | 940 °C |

| Boiling Point | 1351 °C |

Note: We can manufacture and supply different particle sizes (Nano size range, Micron, Submicron, and different Mesh size) products of Alloy powders (Multi-Element, Multi-Element Oxide and Mixture of Rare Earth Elements) according to client’s requirements. Kindly ask for the customization in size and Element ratio composition.

Copper Indium Gallium Alloy Nanopowder

Cu-In-Ga Alloy Nanoparticles/Nanopowder (Particle Size Less than ≤ 80 nm, 99.9%)

Copper Indium Gallium Alloy Nanopowder

| Product Formula | Cu: In: Ga |

| Product Number | NCZ-A-116-19 |

| CAS Number | 7440-50-8/7440-74-6/7440-55-3 |

| Molecular Weight | 248.08 g/moL |

| APS | ≤ 80 nm (can be customized) |

| Purity | 99.9% |

| Color | Grayish Black |

| Form | Nanopowder |

| Density | 1.5 to 1.6 g/cm3 |

| Melting Point | 1145 °C |

| Boiling Point | 1412 °C |

Note: We can manufacture and supply different particle sizes (Nano size range, Micron, Submicron, and different Mesh size) products of Alloy powders (Multi-Element, Multi-Element Oxide and Mixture of Rare Earth Elements) according to client’s requirements. Kindly ask for the customization in size and Element ratio composition.

Copper Indium Sulphur Alloy Nanopowder

| Product Formula | Cu: In: S |

| Product Number | NCZ-A-117-19 |

| CAS Number | 7440-50-8/7440-74-6/7440-34-9 |

| Molecular Weight | 210.42 g/moL |

| APS | ≤ 80 nm (can be customized) |

| Purity | 99.9% |

| Color | Grayish Black |

| Form | Nanopowder |

| Density | 1.5 to 1.8 g/cm3 |

| Melting Point | 1145 °C |

| Boiling Point | 1354 °C |

Note: We can manufacture and supply different particle sizes (Nano size range, Micron, Submicron, and different Mesh size) products of Alloy powders (Multi-Element, Multi-Element Oxide and Mixture of Rare Earth Elements) according to client’s requirements. Kindly ask for the customization in size and Element ratio composition.

Copper Iodide Inorganic Salts Crystal Powder

| Product | Copper Iodide Inorganic Salts Crystal Powder |

| CAS No. | 7681-65-4 |

| Appearance | Powder |

| Purity | 99.9% |

| APS | 1 – 5 Microns (Can be customized) |

| Ingredient | Cul2 |

| Product Code | NCZ-AE-169 |

Copper Metal Organic Framework (Cu (HKUST-1)

| Product Name | Copper Metal Organic Framework |

| Stock No. | NCZMOF105 |

| CAS | 7440-50-8 |

| Purity | 99% |

| APS | 30-40 µm |

| Molecular Formula | C18H6Cu3O12 |

| Molecular Weight | 604.87 g/ mol |

| Odour | Odorless |

| Color | Deep Sky Blue |

| Density | 0.35 g/ cm3 |

| Pore Size | ~10Å |

| SSA | ~1300 m2/g (BET) |

| Solubility | Ethanol |

| Application | Gas Separation, Gas Storage, Drug Delivery, Catalysis, and Sensing. |

| Linker | Benzene-1, 3, 5-tricarboxylic acid (H3BTC) and 4, 4’, 4”, s-triazine- 3, 4, 6- triyltribenzoic acid (H3TATB) |

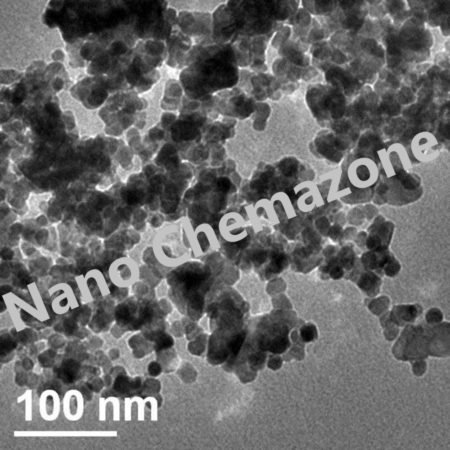

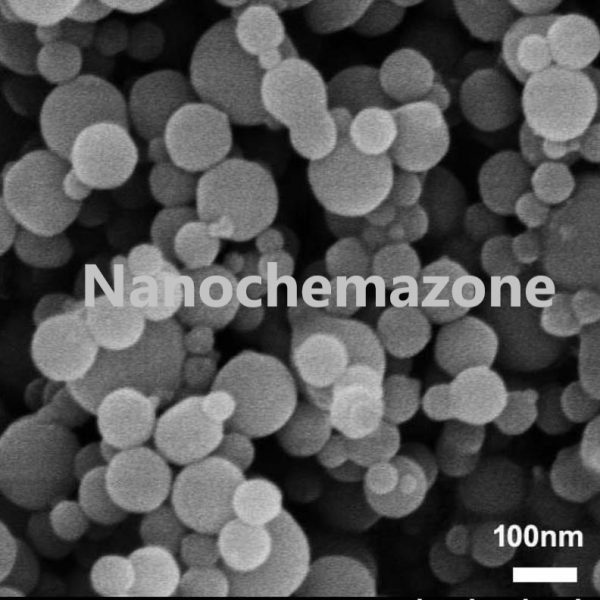

Copper Nanoparticles

Copper Nanoparticles Powder

| MF: | Cu |

| Chemical Name: |

Copper Nanoparticles |

| Purity: | > 99.99% |

| APS: | 25 nm (Size Customization possible) |

| Form: | Nanopowder/Dispersion |

| Product Number: | #NCZ2101 |

| CAS Number | 7440-50-8 |

Application:

The key applications of copper nanoparticles are listed below:

Copper nanoparticles based ink for screen printed circuits and electrode fabrication for electrochemistry.

Acts as an antibiotic, anti-microbial, and anti-fungal agent when added to plastics, coatings, and textiles. Copper diet supplements with efficient delivery characteristics. High strength metals and alloys.

Copper plays an important role in electronic circuits because of its excellent electrical conductivity and ideal material for Thermal, electronic, and biomedical applications such as antimicrobial, Dental Health care and antiviral mask, and gloves coating.

Please contact us for customization and price inquiry.

Note: We supply different size products of micro and Nano Size range dispersion according to the client’s requirements.

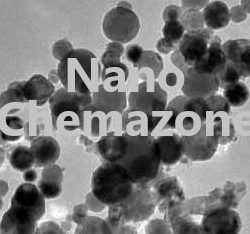

Copper Nanoparticles Dispersion

Copper Nanoparticles Dispersion

| MF: | Cu |

| Chemical Name: | Copper Dispersion |

| Purity: | >99.99% |

| APS: | 50 nm (Size Customization possible) |

| Form: | Nano dispersion |

| Product Number: | NCZD401 |

| CAS Number | 7440-22-4 |

Copper Nanoparticles Applications:

The key applications of copper nanoparticles are listed below:

Copper nanoparticles based ink for screen printed circuits and electrode fabrication for electrochemistry.

Acts as an anti-biotic, anti-microbial, and anti-fungal agent when added to plastics, coatings, and textiles. Copper diet supplements with efficient delivery characteristics. High strength metals and alloys.

Copper plays an important role in electronic circuits because of its excellent electrical conductivity and ideal material for Thermal, electronic, and biomedical applications such as antimicrobial, Dental Health care and antiviral mask, and gloves coating.

Please contact us for customization and price inquiry.

Note: We supply different size products of micro and Nano Size range dispersion according to the client’s requirements.

Copper Nanoparticles Ink

Copper Nanoparticles Ink

Copper Nanoparticles Paste

| MF: | Cu |

| Chemical Name: | Copper Nanoparticles ink |

| Purity: | >99.99% |

| APS: | < 80 nm (Size Customization possible) |

| Form: | viscous liquid |

| Product Number: | NCZD501 |

| CAS Number | 7440-50-8 |

Copper Nanoparticles Applications:

The key applications of copper nanoparticles are listed below:

Copper nanoparticles based ink for screen printed circuits and electrode fabrication for electrochemistry.

Acts as an anti-biotic, anti-microbial, and anti-fungal agent when added to plastics, coatings, and textiles. Copper diet supplements with efficient delivery characteristics. High strength metals and alloys.

Copper plays an important role in electronic circuits because of its excellent electrical conductivity and ideal material for Thermal, electronic, and biomedical applications such as antimicrobial, Dental Health care and antiviral mask, and gloves coating.

Please contact us for customization and price inquiry.

Note: We supply different size products of micro and Nano Size range dispersion according to the client’s requirements.

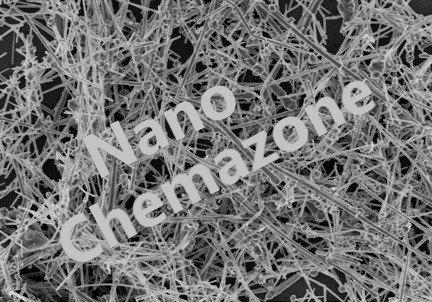

Copper Nanowire

| MF: | Cu |

| Chemical Name: | Copper Nanowires |

| Purity: | > 99.99% |

| Diameter: | 40-50 nm |

| Length: | 40-50 µm |

| Form: | Nanowire |

| Product Number: | NCZW105 |

| CAS Number | 7440-50-8 |

Copper Nanowires

| MF: | Cu |

| Chemical Name: | Copper Nanowires |

| Purity: | > 99.99% |

| Diameter: | 100-200 nm (Customization is possible) |

| Length: | 5-10 µm (Customization is possible) |

| Form: | Nanowire |

| Product Number: | NCZW104 |

| CAS Number | 7440-50-8 |

Copper Nickel Alloy Nanopowder

Copper Nickel Alloy Nanopowder

Copper Nickel (Cu: Ni) Alloy Nanoparticles

| MF: | Cu:Ni |

| Chemical Name: | Copper Nickel Alloy Nanopowder |

| Purity: | > 99.99% |

| APS: | <100 nm (Size Customization possible) |

| Form: | Nanopowder |

| Product Number: | NCZA109 |

| CAS Number: | 7440-50-8 / 7440-02-0 |

Copper Oleate Powder

| Product | Copper Oleate Powder |

| CAS No. | 7440-50-8 |

| Appearance | Powder |

| Purity | 99.9% |

| APS | 1 – 5 microns (can be customized) |

| Ingredient | C36H66CuO4 |

| Product Code | NCZ-AE-192 |

Copper Oxide Black Powder

| Product | Copper Oxide Black Powder |

| CAS No. | 1317-38-0 |

| Appearance | Powder |

| Purity | 99.9% |

| APS | 1 – 5 Microns (Can be customized) |

| Ingredient | CuO |

| Product Code | NCZ-AE-113 |

Copper oxide nanoparticles

Copper Oxide Nanopowder

Copper Oxide Nanoparticles

Nano Copper Oxide Powder

| MF: | CuO |

| Chemical Name: | Copper Oxide |

| Purity: | > 99.99% |

| APS: | 30-50 nm (Size Customization possible) |

| Form: | Nanopowder/Dispersion |

| Product Number: | #NCZ2301 |

| CAS Number | 1317-38-0 |

Copper Oxide Nanopowder Dispersion

Copper Oxide Nanopowder Dispersion

| Product | Copper Oxide Water Dispersion |

| CAS No. | 7440-50-8 |

| Appearance | Black |

| Purity | 99.9% |

| APS | 25-55 nm (Can be customized) |

| Ingredient | CuO |

| Product Code | NCZ-NSC451/20 |

Copper Oxide Dispersion Description

Copper Oxide Water Dispersion antifungal/antibacterial activities that are not observed in commercial copper. First of all, copper nanoparticles demonstrate a very strong catalytic activity, a property that can be attributed to their large catalytic surface area. With the small size and great porosity.

The nanoparticles are able to achieve a higher reaction yield and a shorter reaction time when utilized as reagents in organic and organometallic synthesis. In fact, copper nanoparticles that are used in a condensation reaction of iodobenzene attained about 88% conversion to biphenyl, while the commercial copper exhibited only a conversion.

Copper Oxide Water Dispersion that is extremely small and has a high surface to volume ratio can also serve as an antifungal/antibacterial agents. The antimicrobial activity is induced by their close interaction with microbial membranes and their metal ions released in solutions.

Copper Oxide Water Dispersion slowly in solutions, cupric ions are released from them and they can create toxic hydroxyl free radicals when the lipid membrane is nearby. Copper Oxide Water Dispersion radicals disassemble lipids in cell membranes through oxidation to degenerate the membranes. As a result, the intracellular substances seep out of cells through the destructed membranes.

The cells are no longer able to sustain fundamental biochemical processes. In the end, all these alterations inside of the cell caused by the free radicals lead to cell death.

Copper Oxide Water Dispersion with great catalytic activities can be applied to biosensors and electrochemical sensors. Redox reactions utilized in those sensors are generally irreversible and also require high overpotentials (more energy) to run. In fact, the nanoparticles have the ability to make the redox reactions reversible and to lower the overpotentials when applied to the sensors.

Copper Oxide Dispersion Related Information

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters.Copper Paste

Copper Conductor Paste

Copper Paste for Screen Printing Applications

Copper Paste for Electrodes| Linear Formula: | Cu |

| Chemical Name | Copper Conductor Paste |

| Purity: | >99.99% |

| Molecular Weight | 63.55 |

| Melting Point | 1085 ºC |

| Product Number: | NCZ-P-105 |

| Appearance: | Reddish |

| CAS No: | 7440-50-8 |

Copper Powder

Copper Powder

Copper Powder Nano and Micro size range

| MF: | Cu |

| Chemical Name: | Copper Powder |

| Purity: | > 99.99% |

| APS: | 40-50 µm (Size Customization possible) |

| Form: | Micro powder |

| Product Number: | NCZM108 |

| CAS Number | 7440-50-8 |

Copper Powder Applications:

The key applications of copper metal particles are listed below:

Copper micro and nanoparticles based ink for screen printed circuits and electrode fabrication for electrochemistry.

Acts as an anti-biotic, anti-microbial, and anti-fungal agent when added to plastics, coatings, and textiles. Copper diet supplements with efficient delivery characteristics. High strength metals and alloys.

Copper plays an important role in electronic circuits because of its excellent electrical conductivity and ideal material for Thermal, electronic, and biomedical applications such as antimicrobial, Dental Health care and antiviral mask, and gloves coating.

Note: We can supply different size products of micro and Nano Size range powder according to the client’s requirements.Copper Silica core/shell Nanoparticles

Copper Silica Core-Shell Nanoparticles

| MF: | Cu/SiO2 |

| Chemical Name: | Copper Silica Core-Shell Nanoparticles |

| Purity: | > >99.99% |

| APS: | 80-100 nm (Size Customization possible) |

| Form: | Nanopowder/Nanodispersion |

| Product Number: | NCZCS109 |

| CAS Number: | 7440-50-8/7631-86-9 |

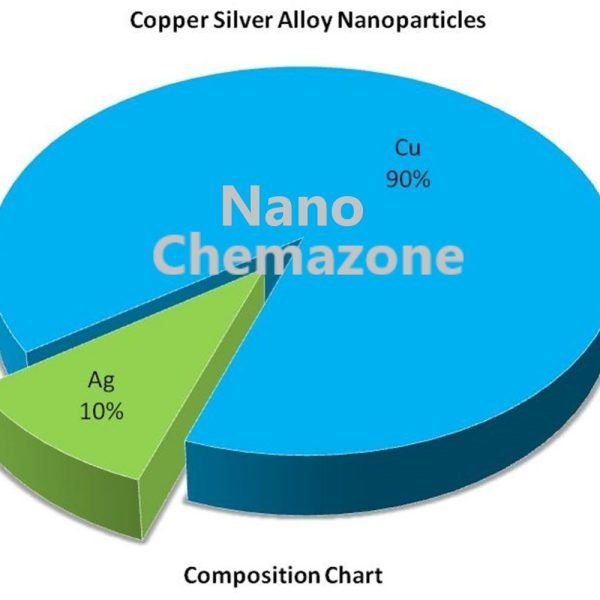

Copper Silver Alloy Nanopowder

Copper Stannate Powder

Copper Stannate Powder

| Product | Copper Stannate Powder |

| CAS No. | 12019-07-7 |

| Appearance | Off-White Powder |

| Purity | ≥99%, ≥99.9%, ≥95% (Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | CuSnO3 |

| Density | N/A |

| Molecular Weight | 230.25g/mol |

| Product Codes | NCZ-MNO-198/25 |

Copper Stannate Description:

Copper Stannate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.Copper Stannate Powder Related Information:

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Copper Stannate Powder (CAS 12019-07-7)| Catalog No. | NCZ-MNO-198/25 |

| CAS Number | 12019-07-7 |

| Molecular Formula | CuSnO3 |

| Molecular Weight | 230.25 |

| Appearance | Solid |

| Purity | 99.5% |

| Physicochemical Information | |

| Density | N/A |

| Melting Point | N/A |

| Water Solubility | N/A |

| InChIKey | SANVPINBICRLAX-UHFFFAOYSA-N |

| Symbol | GHS07 |

| Signal word | Warning |

| Hazard statements | N/A |

| Precautionary statements | P261-P304+P340-P405-P403+P233-P501 |

| Personal protective equipment | N/A |

| RIDADR | UN 2291 6.1/PG 3 |

| WGK Germany | WGK 3 |

Copper Stannate Powder

Copper Stannate Powder

| Product | Copper Stannate Powder |

| CAS No. | 12019-07-7 |

| Appearance | Off- White Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | CuSnO3 |

| Density | N/A |

| Molecular Weight | 330.25g/mol |

| Product Codes | NCZ-DCY-141/25 |

Copper Stannate Description:

Copper Stannate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricingCopper Stannate Powder Related Information :

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Chemical Properties: Other Name: Cupric Stannate CAS: 12019-07-7 Formula: CuSnO3| Item | Unit | Spec |

| Purity | wt% | ≥99 |

| Particle size (D50 ) | μm | <0.3 |

| Fe2O3 | wt% | <0.01 |

| Pb | wt% | <0.01 |

| S | wt% | <0.01 |

| Cl | wt% | <0.01 |

| H20 | wt% | <0.5 |

| Ignition loss | wt% | <1.0 |

Copper Tin Alloy Nanopowder

Copper Zinc Alloy Nano Dispersion

| Product Number | NCZ-D-1503N |

| CAS | 53801-63-1 |

| APS | 50 nm (Size Customisation is Possible) |

| Purity | 99.99% |

| Molecular Formula | Zn Cu |

| Molecular Weight | 128.93g/mol |

| Form | Liquid |

| Colour | Dark Gray/brown |

| Concentration | 100 ppm |

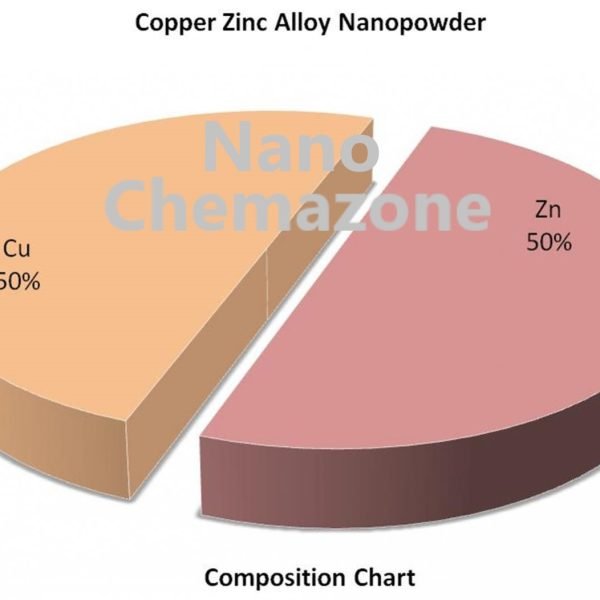

Copper Zinc Alloy Nanoparticles

| MF: | Cu:Zn |

| Chemical Name: |

Copper Zinc Alloy Nanoparticles |

| Purity: | > 99.99% |

| APS: | <80 nm, APS 10 micron (Size Customization possible) |

| Form: | Nanopowder |

| Product Number: | NCZA113 |

| CAS Number: | 7439-89-6 / 7440-47-3 / 7440-48-4 |

Copper Zirconium Alloy Nanopowder

Copper Zirconium Alloy Nanopowder

Product Name: Cu-Zr Alloy Nanoparticles/Nanopowder (Particle Size Less than ≤ 80 nm, 99.9%)

| Product Formula | Cu: Zr |

| Product Number | NCZ-A-124-19 |

| CAS Number | 7440-50-8/7440-67-7 |

| Molecular Weight | 154.77 g/moL |

| APS | ≤ 80 nm (can be customized) |

| Purity | 99.9% |

| Color | Grayish |

| Form | Nanopowder |

Note: We can manufacture and supply different particle sizes (Nano size range, Micron, Submicron, and different Mesh size) products of Alloy powders (Multi-Element, Multi-Element Oxide and Mixture of Rare Earth Elements) according to client’s requirements. Kindly ask for the customization in size and Element ratio composition.

Copper(I) Acetate Powder

Copper(I) Acetate Powder

| Product | Copper(I) Acetate Powder |

| CAS No. | 598-54-9 |

| Appearance | White to Green to Brown Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | CuC2H3O2 |

| Density | N/A |

| Molecular Weight | 122.59g/mol |

| Product Code | NCZ-CAS-146/25 |

Copper(I) Acetate Description:

Copper(I) Acetate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.Copper(I) Acetate Powder Related Information:

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Copper(I) Acetate CAS #: 598-54-9 Linear Formula:CuCO2CH3 MDL Number:MFCD00058908 EC No.:209-938-7 Copper(I) Acetate Properties (Theoretical)| Compound Formula | C2H3CuO2 |

| Molecular Weight | 122.59 |

| Appearance | White to green to brown powder or chunks |

| Melting Point | 250°C (dec.) |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | N/A |

| Exact Mass | 121.942902 |

| Monoisotopic Mass | 121.942902 |

Copper(II) Acetate Hydrate Powder

Copper(II) Acetate Hydrate Powder

| Product | Copper(II) Acetate Hydrate Powder |

| CAS No. | 66923-66-8 |

| Appearance | Blue Crystal Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | Cu(C2H3O2)2.H2O |

| Density | 1.88g/cm3 |

| Molecular Weight | 199.65g/mol |

| Product Code | NCZ-CAS-148/25 |

Copper(II) Acetate Hydrate Description:

Copper(II) Acetate Hydrate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.Copper(II) Acetate Hydrate Powder Related Information:

Storage Conditions: Airtight sealed,avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Copper(II) Acetate Hydrate CAS #: 66923-66-8 Linear Formula: Cu(C2H3O2)2 • xH2O MDL Number:MFCD00149570 EC No.:205-553-3 Copper(II) Acetate Hydrate Properties (Theoretical)| Compound Formula | C4H8CuO5 |

| Molecular Weight | 199.65 |

| Appearance | Blue Crystals |

| Melting Point | 116 °C |

| Boiling Point | 240 °C |

| Density | 1.88 g/cm3 |

| Solubility in H2O | 72 g/l (20 °C) |

| pH | 5.2-5.5 (20 g/l aq. sol) |

| Vapor Density | 6.8-6.9 (vs. air) |

| Exact Mass | 198.966771 |

| Monoisotopic Mass | 198.966771 |

Copper(II) Acetate Monohydrate Powder

Copper(II) Acetate Monohydrate Powder

| Product | Copper(II) Acetate Monohydrate Powder |

| CAS No. | 6046-93-1 |

| Appearance | Blue Crystal Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | Cu(CH3OO)2.H2O |

| Density | 1.88g/cm3 |

| Molecular Weight | 199.65g/mol |

| Product Code | NCZ-CAS-149/25 |

Copper(II) Acetate Monohydrate Description:

Copper(II) Acetate Monohydrate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.Copper(II) Acetate Monohydrate Powder Related Information:

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Copper(II) Acetate Monohydrate CAS #: 6046-93-1 Linear Formula: Cu(C2H3O2)2 • H2O MDL Number:MFCD00149570 EC No.:205-553-3 Copper(II) Acetate Monohydrate Properties (Theoretical)| Compound Formula | C4H8CuO5 |

| Molecular Weight | 199.65 |

| Appearance | Blue Crystals |

| Melting Point | 116 °C |

| Boiling Point | 240 °C |

| Density | 1.88 g/cm3 |

| Solubility in H2O | 72 g/l (20 °C) |

| pH | 5.2-5.5 (20 g/l aq. sol) |

| Vapor Density | 6.8-6.9 (vs. air) |

| Exact Mass | 198.966771 |

| Monoisotopic Mass | 198.966771 |

Copper(II) Acetate Powder

Copper(II) Acetate Powder

| Product | Copper(II) Acetate Powder |

| CAS No. | 142-71-2 |

| Appearance | Blue Crystal Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | Cu(OAc)s |

| Density | 1.88g/cm3 |

| Molecular Weight | 181.63g/mol |

| Product Code | NCZ-CAS-147/25 |

Copper(II) Acetate Description:

Copper(II) Acetate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.Copper(II) Acetate Powder Related Information:

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Copper(II) Acetate CAS #: 142-71-2 Linear Formula: Cu(C2H3O2)2 MDL Number:MFCD00008690 EC No.:205-553-3 Copper(II) Acetate Properties (Theoretical)| Compound Formula | C4H6CuO4 |

| Molecular Weight | 181.63 |

| Appearance | Blue Crystals |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | 1.88 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 180.956 g/mol |

| Monoisotopic Mass | 180.956 g/mol |

Copper(II) Trifluoroacetate Hydrate Powder

Copper(II) Trifluoroacetate Hydrate Powder

| Product | Copper(II) Trifluoroacetate Hydrate Powder |

| CAS No. | 123333-88-0 |

| Appearance | Blue Crystal Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | Cu(CO2CF3)2.xH2O |

| Density | N/A |

| Molecular Weight | 309.61g/mol |

| Product Code | NCZ-CAS-150/25 |

Copper(II) Trifluoroacetate Hydrate Description:

Copper(II) Trifluoroacetate Hydrate Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.Copper(II) Trifluoroacetate Hydrate Powder Related Information:

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. Copper(II) Trifluoroacetate Hydrate CAS #: 123333-88-0 Linear Formula: Cu(CO2CF3)2• xH2O MDL Number:MFCD00167308 EC No.:205-553-3 Copper(II) Trifluoroacetate Hydrate Properties (Theoretical)| Compound Formula | C4H4CuF6O5 |

| Molecular Weight | 309.61 |

| Appearance | Solid |

| Melting Point | N/A |

| Boiling Point | N/A |

| Density | N/A |

| Solubility in H2O | N/A |

| Exact Mass | 308.92589 g/mol |

| Monoisotopic Mass | 308.92589 g/mol |

| Charge | 0 |

CPTi Powder

CPTi Powder

| Product | CPTi Powder |

| CAS No. | 12083-20-1 |

| Appearance | White -Silvery Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | Cp-Ti |

| Density | 4.51g/cm3 |

| Molecular Weight | 41.86g/mol |

| Product Codes | NCZ-DCY-312/25 |

CPTi Description:

CPTi Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.CPTi Powder Related Information :

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. CPTi Powder CPTi (chemically pure titanium) powder is a high purity titanium metal powder used in various applications requiring excellent corrosion resistance, high strength, low weight, and biocompatibility. It offers superior properties compared to other titanium grades and alloy powders. Overview of CPTi Powder CPTi (chemically pure titanium) powder is a high purity titanium metal powder used in various applications requiring excellent corrosion resistance, high strength, low weight, and biocompatibility. It offers superior properties compared to other titanium grades and alloy powders. CPTi powder is produced by gas atomization process to achieve spherical powder morphology with minimal contamination. It has a particle size range of 15-150 microns generally. The high purity and cleanliness result in excellent flowability, packing density and sinterability. Some key properties and advantages of CPTi powder include: CPTi Powder Properties and Characteristics| Properties | Details |

| Composition | 99.5% minimum Titanium. Low O, C, N, H, Fe impurities |

| Density | 4.5 g/cc |

| Flowability | Excellent due to spherical morphology |

| Sinterability | Excellent, achieves near full density |

| Particle shape | Predominantly spherical |

| Particle size range | 15-150 microns |

| Apparent density | 2.7-3.2 g/cc |

| Purity | Up to 99.995% Ti content |

| Impurities | Low oxygen, nitrogen, carbon, iron |

| Color | Dark gray with metallic luster |

| Element | Weight % |

| Titanium | 99.5% min |

| Oxygen | 0.08% – 0.40% |

| Carbon | 0.03% – 0.08% |

| Nitrogen | 0.01% – 0.05% |

| Hydrogen | 0.005% – 0.015% |

| Iron | 0.05% – 0.25% |

| Grade | Purity | Particle Size | Applications |

| CPTi Grade 1 | 99.5% min | Medium, large | General use |

| CPTi Grade 2 | 99.9% | Fine, medium | Aerospace, medical |

| CPTi Grade 3 | 99.95% | Fine | Medical, dental |

| CPTi Grade 4 | 99.99% | Ultrafine | Implants, high purity uses |

| Properties | Values |

| Density | 4.5 g/cc |

| Melting point | 1668°C |

| Thermal conductivity | 21.9 W/mK |

| Electrical resistivity | 53.8 ohm-cm |

| Young’s modulus | 107 GPa |

| Poisson’s ratio | 0.33 |

| Mohs hardness | 6 |

| Oxidation resistance | Up to 590°C in air |

| Properties | Values |

| Tensile strength | 420 – 550 MPa |

| Yield strength | 380 – 470 MPa |

| Elongation | 15 – 30% |

| Hardness | 200-240 HV |

| Fatigue strength | 200-300 MPa |

| Industry | Application Examples |

| Aerospace | Engine components, airframe parts, fasteners |

| Medical | Implants, prosthetics, instruments |

| Automotive | Valves, connecting rods, springs |

| Chemical | Pumps, valves, tanks, pipes |

| 3D printing | Aerospace and medical components |

| Metal injection molding | Dental instruments, hardware |

| Investment casting | Turbine blades, golf club heads |

| Standard | Description |

| ASTM B348 | Standard specification for titanium and titanium alloy powders |

| ASTM F67 | Standard specification for unalloyed titanium bars for surgical implants |

| ISO 5832-2 | Implant grade wrought titanium materials |

| Particle size | Typical size range | Applications |

| Fine | 1-25 microns | Investment casting, MIM |

| Medium | 25-45 microns | Press and sinter, HIP |

| Coarse | 45-150 microns | Thermal and cold spraying |

| Apparent Density | Characteristics |

| 2.7 – 3.0 g/cc | Unalloyed CPTi powder |

| 3.0 – 3.2 g/cc | Alloyed CPTi powder |

| Up to 50% of true density | Due to voids between particles |

| Method | Details |

| Gas atomization | High pressure argon gas disintegrates molten Ti stream into fine droplets, which solidify into spherical powder |

| Vacuum arc melting | High purity Ti input stock is refined to reduce gaseous impurities like O, N, H |

| Multiple melting | Ensures chemical homogeneity of raw material |

| Sieving | Classifies powder into different particle size distributions |

| Blending | Powders with different particle sizes are mixed in optimized ratios |

| Recommendation | Reason |

| Avoid inhalation | Due to small particle size |

| Use protective masks | Prevent ingestion through nose/mouth |

| Conduct handling in ventilated areas | Reduce airborne powder circulation |

| Use hazmat suits in large operations | Minimize skin contact |

| Ensure no ignition sources nearby | Powder can combust in oxygen atmosphere |

| Follow anti-static protocols | Prevent accidental fire due to buildup of static charge |

| Use non-sparking tools | Avoids possibility of ignition during handling |

| Store sealed containers in cool, dry area | Prevents moisture pickup and reactivity |

| Test | Details |

| Chemistry analysis | ICP spectroscopy verifies elemental composition |

| Particle size distribution | Sieve analysis determines size distribution |

| Apparent density | Measured as per ASTM B212 standard |

| Powder morphology | Scanning electron microscopy verifies spherical shape |

| Flow rate | Time taken for fixed powder quantity to flow through defined nozzle |

| Tap density | Density measured after mechanically tapping powder sample |

| Compressibility | Monitoring of powder bed density change during compression |

| Factor | Effect |

| Air, oxygen | Moderate oxidation risk above 500°C |

| Moisture | Low corrosion rate at room temperature |

| Hydrocarbons | Risk of fire if allowed to contaminate powder |

| Acids, bases | Low corrosion rates in neutral solutions |

| Organic solvents | Some absorption and discoloration if immersed |

| Elevated temperatures | Increased reactivity with oxygen and nitrogen |

| Parameter | CPTi Powder | Ti-6Al-4V Powder |

| Density | 4.5 g/cc | 4.42 g/cc |

| Tensile strength | 420 – 550 MPa | 950 – 1050 MPa |

| Ductility | 15 – 30% | 10 – 18% |

| Fatigue strength | 200 – 300 MPa | 500 – 600 MPa |

| Corrosion resistance | Excellent | Moderate |

| Oxidation resistance | Excellent | Good |

| Cost | Low | Moderate |

| Toxicity | None | Low |

| Uses | Low temperature applications, prosthetics | Aerospace components, automotive parts |

Cr2AlC MAXene Powder

Product Name: Cr2AlC MAXene Powder

| Product |

Cr2AlC MAXene |

| Colour | Black Powder |

| Purity | ≥98 wt% |

| Ingredient | Cr2AlC |

| Product Code | NCZ-MX-113 |

Cr2AlC MAXene powder APPLICATION FIELDS

High-temperature coating, MXene precursor, conductive self-lubricating ceramic, lithium-ion battery, supercapacitor, electrochemical catalysis. RELATED INFORMATION Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please email us for the customization. Email: contact@nanochemazone.comCr2C MXenes

Product Name: Cr2C MXenes

Product Code: NCZ-MX-201

| Product | Cr2C MXene |

| Colour | Black Powder |

| Purity | ≥98 wt% |

| Ingredient | Cr2C |

| CAS NO | 12316-56-2 |

Cr2C MXenes APPLICATION FIELDS

High-temperature coating, Mxene precursor, conductive self-lubricating ceramic, lithium-ion battery, supercapacitor, electrochemical catalysis.RELATED INFORMATION

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please email us for the customization. Email: contact@nanochemazone.comCVD Graphene on Copper Foil

| Sheet Resistance | <600Ω/sq |

| Custom Order | <300Ω/sq |

| Transparency | >95% |

| Product Name |

CVD Graphene on Copper Foil |

| Stock No. | NCZ-GSW-0016 |

| Purity | > 99.9% |

| Graphene Film | |

| FET Electron Mobility on Al2O3 | 2000 cm2/Vs |

| Hall Electron Mobility on SiO2/Si | 4000 cm2/Vs |

CVD Graphene on PET Substrate

| Product Name |

CVD Graphene on PET Substrate |

| Stock No. | NCZ-GSW-0019 |

| Purity | > 99.9% |

| Graphene Film | |

| FET Electron Mobility on Al2O3 | 2000 cm2/Vs |

| Hall Electron Mobility on SiO2/Si | 4000 cm2/Vs |

| Sheet Resistance | <600Ω/sq |

| Custom Order | <300Ω/sq |

| Transparency | >95% |

CVD Graphene on Quartz Substrate

| Product Name |

CVD Graphene on Quartz Substrate |

| Stock No. | NCZ-GSW-0020 |

| Purity | > 99.9% |

| Graphene Film | |

| FET Electron Mobility on Al2O3 | 2000 cm2/Vs |

| Hall Electron Mobility on SiO2/Si | 4000 cm2/Vs |

| Sheet Resistance | <600Ω/sq |

| Custom Order | <300Ω/sq |

| Transparency | >95% |

| CVD Graphene | Substrate |

| 1cm x 1cm | Diameter: 1inch, Thickness: 3mm* |

| 1inch x 1inch | 30mm x 30mm, Thickness: 1mm |

CVD Graphene on Silicon Substrate

| Product Name |

CVD Graphene On Silicon Substrate |

| Stock No. | NCZ-GSW-0017 |

| Purity | > 99.9% |

| Graphene Film | |

| FET Electron Mobility on Al2O3 | 2000 cm2/Vs |

| Hall Electron Mobility on SiO2/Si | 4000 cm2/Vs |

| Sheet Resistance | 450±40 Ω/sq (1cm x1cm) |

| Transparency | >95% |

- Copper-based graphene is prepared by CVD method.

- Graphene is transferred from copper to silicon substrate.

SILICON WAFER:

| Wafer Thickness: | 525 µm, (customization is possible) |

| Resistivity: | <0.01 ohm-cm |

| Type/Dopant: | P/N |

| Orientation: | <100> (customization is possible) |

| Front Surface: | Polished |

| Back Surface: | Etched |

CVD Graphene on SiO2 Substrate

| Product Name |

CVD Graphene on SiO2 Substrate/Wafer |

| Stock No. | NCZ-GSW-0018 |

| Purity | > 99.9% |

| Graphene Film | |

| FET Electron Mobility on Al2O3 | 2000 cm2/Vs |

| Hall Electron Mobility on SiO2/Si | 4000 cm2/Vs |

| Sheet Resistance | <600Ω/sq |

| Custom Order | <300Ω/sq |

| Transparency | >95% |

| CVD Graphene | Substrate |

| 1cm x 1cm | 1.5cm x 1.5cm, thickness: 300nm SiO2/700um Si |

| 1inch x 1inch | 3.0cm x 3.0cm, thickness: 300nm SiO2/700um Si |

| 3cm x 3cm | 3.5cm x 3.5cm, thickness: 300nm SiO2/700um Si |

| 7cm x 7cm | Diameter: 4inch, thickness: 300nm SiO2/600um Si |

D2 Powder

D2 Powder

| Product | D2 Powder |

| CAS No. | 7782-39-0 |

| Appearance | White-Off White Powder |

| Purity | ≥99%, ≥99.9%, ≥95%(Other purities are also available) |

| APS | 1-5 µM, 10-53 µM (Can be customized), Ask for other available size range. |

| Ingredient | C28H44O2 |

| Density | 7.7g/cm3 |

| Molecular Weight | N/A |

| Product Codes | NCZ-DCY-350/25 |

D2 Description:

D2 Powder is one of the numerous advanced ceramic materials manufactured by Nanochemazone. Nanochemazone produces too many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available. Additional technical, research and safety (MSDS) information are available. Please request a quote above for more information on lead time and pricing.D2 Powder Related Information :

Storage Conditions: Airtight sealed, avoid light and keep dry at room temperature. Please contact us for customization and price inquiry Email: contact@nanochemazone.com Note: We supply different size ranges of Nano and micron as per the client’s requirements and also accept customization in various parameters. D2 Powder D2 powder is a cold work tool steel powder offering an excellent combination of high hardness, wear resistance, and toughness. It is a versatile chromium-molybdenum-vanadium alloy widely used for pressing into cutting tools, dies, precision parts, and wear components across industrial sectors. Overview of D2 Powder D2 powder is a cold work tool steel powder offering an excellent combination of high hardness, wear resistance, and toughness. It is a versatile chromium-molybdenum-vanadium alloy widely used for pressing into cutting tools, dies, precision parts, and wear components across industrial sectors. Key properties and advantages of D2 powder include: D2 Powder Properties and Characteristics| Properties | Details |

| Composition | Fe-1.5Cr-0.3C-0.4V-1Mo alloy |

| Density | 7.7 g/cc |

| Particle shape | Spherical or irregular |

| Size range | 10-150 microns |

| Apparent density | Up to 60% of true density |

| Flowability | Good |

| Hardness | 60-62 HRC when heat treated |

| Toughness | Very good |

| Element | Weight % |

| Iron (Fe) | Balance |

| Chromium (Cr) | 11-13% |

| Carbon (C) | 1.4-1.6% |

| Molybdenum (Mo) | 0.75-1.2% |

| Vanadium (V) | 0.7-1.2% |

| Manganese (Mn) | 0.3-0.6% |

| Silicon (Si) | 0.15-0.4% |

| Property | Value |

| Density | 7.7 g/cc |

| Melting point | 1460-1500°C |

| Thermal conductivity | 21 W/mK |

| Electrical resistivity | 0.7 μΩ-m |

| Curie temperature | 1010°C |

| Maximum service temperature | 180-200°C |

| Property | Value |

| Hardness | 60-62 HRC |

| Transverse rupture strength | 1900-2100 MPa |

| Tensile strength | 2050-2200 MPa |

| Yield strength | 1700-1900 MPa |

| Elongation | 8-11% |

| Impact toughness | 12-15 J/cm2 |

| Industry | Example Uses |

| Manufacturing | Press tooling, punch and dies |

| Automotive | Blank, pierce, trim, and forming dies |

| Aerospace | Forming dies, fixtures |

| Consumer goods | Razors, knives, scissors |

| Industrial | Drawing dies, thread rolling dies |

| Standard | Description |

| ASTM A681 | Standard for tool steels alloys |

| DIN 1.2379 | Equivalent to AISI D2 |

| JIS G 4404 | Cold work tool steels |

| ISO 4957 | Tool steels |

| GOST 5950 | Tool steel grades |

| Particle Size | Characteristics |

| 10-22 microns | Ultrafine grade provides highest density |

| 22-53 microns | Most commonly used size range |

| 53-105 microns | Coarser size provides good flowability |

| Apparent Density | Details |

| Up to 60% of true density | For spherical powder morphology |

| 4.5-5.5 g/cc typical | Higher density improves flow and compressibility |

| Method | Details |

| Gas atomization | High pressure inert gas breaks up molten alloy stream into fine droplets |

| Vacuum induction melting | High purity input materials melted under vacuum |

| Multiple remelting | Enhances chemical homogeneity |

| Sieving | Classifies powder into different particle size fractions |

| Recommendation | Reason |

| Ensure adequate ventilation | Prevent exposure to fine metal particles |

| Wear protective gear | Avoid accidental ingestion |

| Ground all equipment | Prevent static sparks |

| Avoid ignition sources | Flammable dust risk |

| Use non-sparking tools | Prevent ignition during handling |

| Follow safe protocols | Reduce fire, explosion, and health risks |

| Test | Details |

| Chemical analysis | Verifies composition using optical or ICP spectroscopy |

| Particle size distribution | Determines sizes using laser diffraction or sieving |

| Apparent density | Measured using Hall flowmeter as per ASTM B212 |

| Powder morphology | SEM imaging to determine particle shape |

| Flow rate analysis | Gravity flow rate through specified funnel |

| Tap density test | Density measured after mechanically tapping powder sample |

| Parameter | D2 | S7 |

| Hardness | 60-62 HRC | 63-65 HRC |

| Toughness | Very good | Good |

| Wear resistance | Excellent | Outstanding |

| Corrosion resistance | Moderate | Low |

| Cold strength | Excellent | Very good |

| Cost | Low | High |

Devarda Alloy Powder

| MF: | Al:Cu:Zn |

| Chemical Name: |

Devarda Alloy Powder |

| Purity: | > 99.9% |

| APS: | 80-100 nm (Size Customization possible) |

| Form: | Nanopowder |

| Product Number: | NCZA114 |

| CAS Number: | 8049-11-4 |

![Di-μ-chlorobis[2-[(dimethylamino)methyl]phenyl-C,N] Dipalladium(II) Powder](https://nanochemazone.ca/wp-content/uploads/2025/04/Di-μ-chlorobis2-dimethylaminomethylphenyl-CN-DipalladiumII-Powder.jpg)

![Diacetato[1,3-bis(diphenyl phosphino)]propane Palladium(II) Powder](https://nanochemazone.ca/wp-content/uploads/2025/03/Diacetato13-bisdiphenyl-phosphinopropane-PalladiumII-Powder.jpg)